Independent laboratory test results reveal that PPG TESLIN® substrate affords faster static decay, is static dissipative, increases productivity and helps with workplace safety.

Surface Resistivity*

The surface resistivity test determines the electrical surface resistivity of a solid material under different conditions of relative humidity. Since the time it takes for an electrostatically charged surface to lose its charge to ground by conduction is directly related to its electrical surface resistivity (and volume resistivity), this test can be used to assess electrostatic hazards that may exist in any given application.

| Substrate | Average at 12% RH (Ohms/square) | Average at 16% RH (Ohms/square) | Average at 50% RH (Ohms/square) | Average at 71% RH (Ohms/square) |

|---|---|---|---|---|

| Teslin | 7.87 x 1012 | 6.31 x 1012 | 5.32 x 1010 | 1.93 x 1009 |

| PVC | 5.52 x 1013 | 4.93 x 1013 | ||

| PET | > 1 x 1015 | 7.97 x 1013 | ||

| PC | 4.8 x 1014 | n/a | 5.5 x 1014 | n/a |

The test was conducted according to American Society for Testing and Materials (ASTM) D257.

Per EIA-541, between 1 x 105 & 1 x 1012 Ohms/square is static dissipative

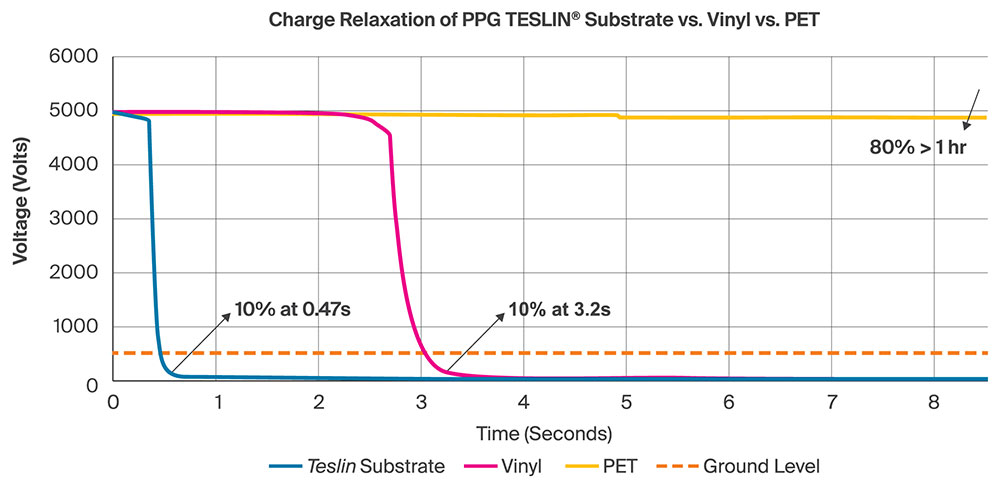

Charge Relaxation (Decay) Time

This test measures the time needed to dissipate the electrostatic charge from the surface of a material to ground (earth).

| Substrate | Static Decay Time at 12% RH (Seconds) | Static Decay Time at 16% RH (Seconds) | Static Decay Time at 50% RH (Seconds) | Static Decay Time at 71% RH (Seconds) |

|---|---|---|---|---|

| Teslin | 23.4 | 35.33 | 0.05 | 0.47 |

| PVC | Does not decay | 42.8 | Does not decay | 3.2 |

| PET | Does not decay | >1 hour | Does not decay | >1 hour |

| PC | Does not decay | Does not decay |

This test was conducted according to MIL-STD-3010C, test method 4046.

Per MIL-STD-3010 specification, acceptable static decay materials should exhibit static decay time of < 0.50 seconds when conditioned at 50% RH

This test was performed in accordance with MIL-STD-3010C, test method 4046.

Test summary

At 71% relative humidity, in less than 0.5 seconds Teslin substrate dissipated more than 90% of its starting charge of 5000V. Both PET and vinyl held approximately 100% of their starting charge of 5000V over the same amount of time and showed minimal tendency to dissipate their charge. Although vinyl eventually dissipates its charge, it takes more than 3 seconds and does not meet the static dissipative definition of an electrostatic material.

Label Peel Test

Label peel testing determines the electrostatic charge build up when an electrically isolated label set is peeled off from its backing and placed in a Faraday Cage under different conditions of relative humidity. The specific charge density calculated was then compared with maximum surface charge density (charge per unit area of 2.7x10-5 Coulomb/m2) in free space.

| Results | ||||

|---|---|---|---|---|

| Test | Substrate | Ambient RH | Low RH (16%) | Comments |

| Label Peel Test / Charge Density (ASTM D4470) (Coulomb/m2) |

PPG Teslin label w/ backer | 0.0000000175 | 0.00000965 | Not highly chargeable at ambient RH but highly chargeable at low RH |

| Vinyl label | 0.0000073 | 0.0000088 | Highly chargeable at both ambient and low RH | |

| PET label | 0.00000752 | 0.0000093 | Highly chargeable at both ambient and low RH | |

This test was performed in accordance with ASTM D257 and conforms to the ISO 17025:2017 standard.

Test summary

When peeled from their backings, vinyl labels can become electrostatically charged to 29% of the maximum charge density possible (2.7x10-5 C/m2) at ambient humidity environments, and PET labels can become charged to 30%. The same test of Teslin labels showed that they only become electrostatically charged to 0.065%. The charge on both the vinyl and PET labels can give rise to incendive electrostatic discharges under ambient and low relative humidity conditions.

Teslin Substrate vs. PVC and PC

| Card Construction | Static Decay Time at 50% RH (Seconds) |

|---|---|

| Teslin/PET | 0.11 |

| Teslin/PVC (with magstripe) | 0.02 |

| All PVC | 6.2 |

| All PC | Does not decay |